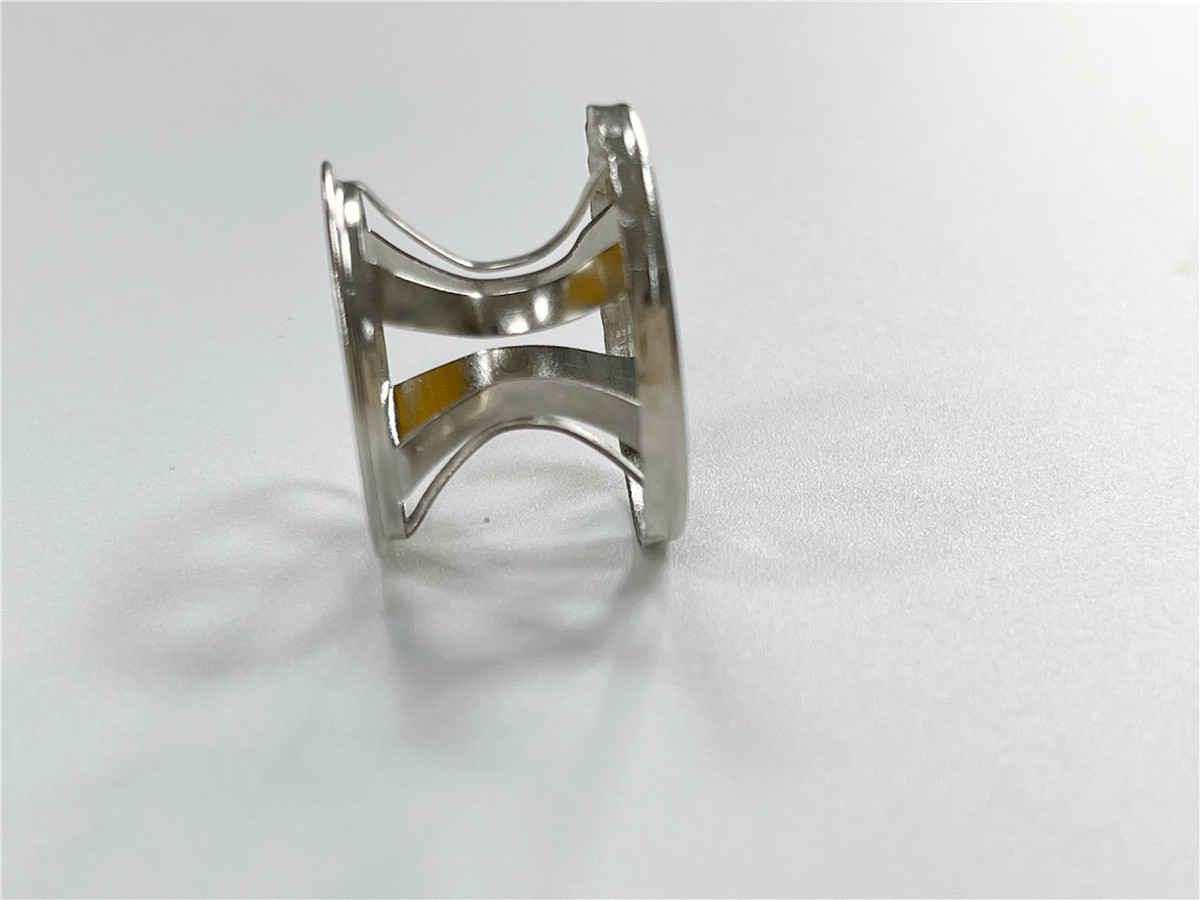

Stamping Stainless Steel Metal Parts

Parameters

| CNC Machining or Not | Cnc Machining | Tolerance | ±0.005-0.01 | ||

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, titanium | Packing | Rust Preventative PP/PE bags Foams Carton boxes Wooden cases Pallets | ||

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping | Materials Avaliable | Aluminum, copper, iron,steel, titanium alloy, POM, ABS, nylon | ||

| Micro Machining or Not | Micro Machining | Logo | Accept Custom Logo | ||

| Model Number | ST013 | Certification | ISO 9001:2015 | ||

| Brand Name | DGCS | Application | Automation equipment | ||

| Processing Type | Milling Turning Machining Casting Stamping | Finishing | polishing anodizing | ||

| Sample | within 7days | Material | metal plastic stainless steel | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10 | 11-100 | 101-1000 | > 1000 |

| Lead time (days) | 5 | 7 | 17 | To be negotiated | |

Product Details

1. Professional CNC processing technology

First of all, the production of stamped stainless steel metal parts adopts professional CNC processing technology. This machining technique allows precise control of each operation step, ensuring the dimensional accuracy of the part. The high precision and stability of CNC processing equipment make the processing process of stamping stainless steel metal parts efficient and reliable, and can meet the strict requirements of customers for precision.

2. Stringent accuracy checks

Second, custom stamped stainless steel metal parts undergo rigorous precision inspections. During the machining process, the part undergoes multiple precision inspections to ensure that it meets the customer's requirements. Only parts that pass these precision checks can be considered qualified products. This accuracy check provides maximum assurance of part quality and stability.

3. Advantages of customized services

In addition, the advantages of customized services for stamped stainless steel metal parts are also reflected in the full range of services it provides. During the customization process, we work closely with our clients to understand their specific needs and requirements. Our professional team will provide customers with personalized consultation and design suggestions, and make modifications and adjustments based on customer feedback until the customer's expectations are met. We not only provide high-quality parts production, but also provide timely delivery and after-sales service to ensure customer satisfaction and trust.

To sum up, the customization of stainless steel metal parts made by professional CNC high-precision machining and stamping has many advantages. It not only has precise and stable processing technology, but also strict precision inspection and comprehensive services make it an ideal choice for all walks of life. We are committed to providing customers with high-quality parts manufacturing and satisfactory service experience to meet customers' requirements for quality and performance.