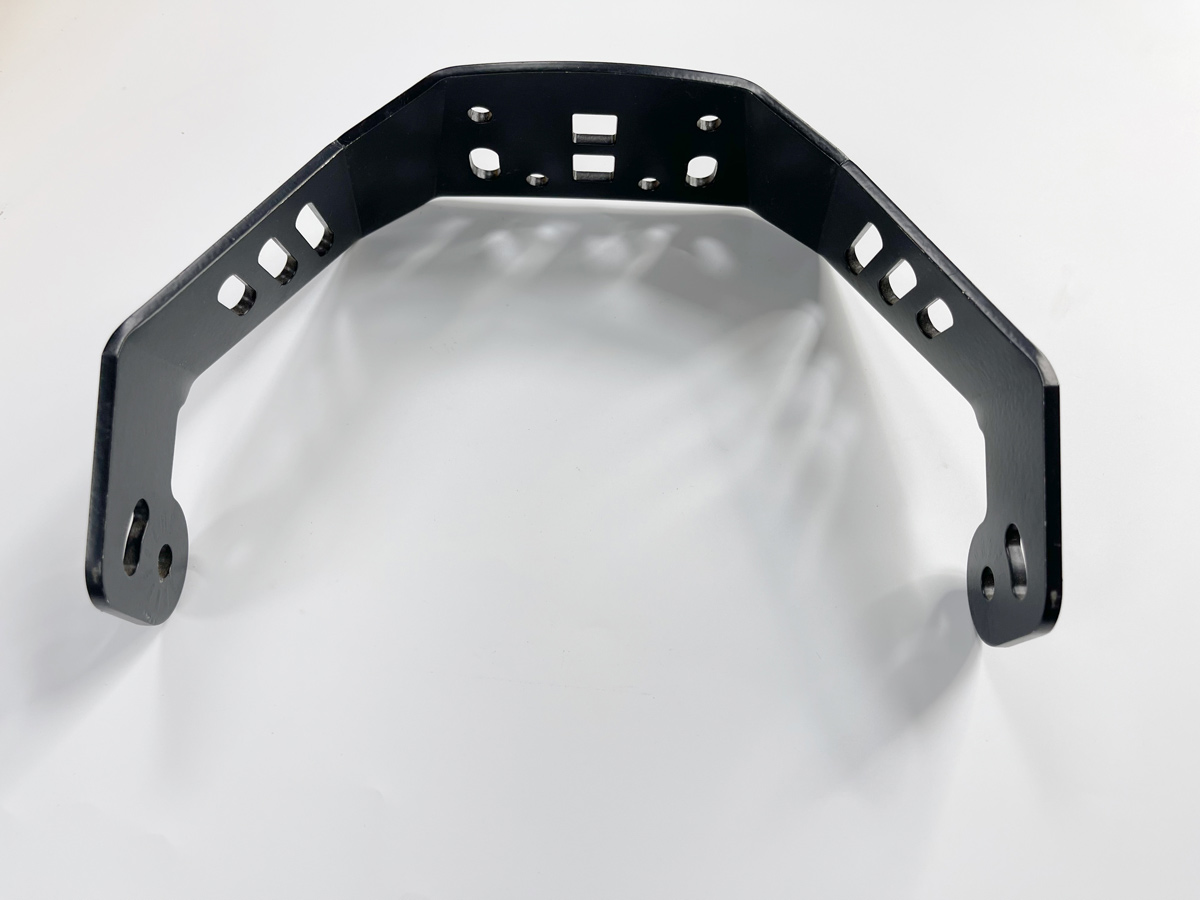

Non-standard Metal Fixing Bracket

Parameters

| CNC Machining or Not | Cnc Machining | Tolerance | ±0.005-0.01 | ||

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, titanium | Packing | Rust Preventative PP/PE bags Foams Carton boxes Wooden cases Pallets | ||

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping | Materials Avaliable | Aluminum, copper, iron,steel, titanium alloy, POM, ABS, nylon | ||

| Micro Machining or Not | Micro Machining | Logo | Accept Custom Logo | ||

| Model Number | ST012 | Certification | ISO 9001:2015 | ||

| Brand Name | DGCS | Application | Automation equipment | ||

| Processing Type | Stamping Milling Turning Machining Casting | Finishing | polishing anodizing | ||

| Sample | within 7days | Material | metal plastic stainless steel | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10 | 11-100 | 101-1000 | > 1000 |

| Lead time (days) | 5 | 7 | 17 | To be negotiated | |

Product Details

1. High-quality materials and stamping and bending process

The part is constructed of stainless steel and aluminum for durability and corrosion resistance. Its stamping and bending process is realized through advanced CNC machining technology, which ensures precision and consistency. The process also enables the realization of complex shapes and details to meet the specific needs of customers. The part is finely designed with compact structure and solid strength. Its shape and size are precisely calculated to ensure that it is suitable for the installation requirements of different equipment. The part is constructed of stainless steel and aluminum for durability and corrosion resistance.

2. Easy installation

Its stamping and bending process is realized through advanced CNC machining technology, which ensures precision and consistency. The process also enables the realization of complex shapes and details to meet the specific needs of customers. The part is finely designed with compact structure and solid strength. Its shape and size are precisely calculated to ensure that it is suitable for the installation requirements of different equipment.

All in all, this customized stamping bending CNC machining non-standard stainless steel aluminum metal fixing bracket rack part is a high-quality, high-efficiency component that can be widely used in various equipment. Its precision machining process, stable support function and durability make it an ideal choice for various industries.