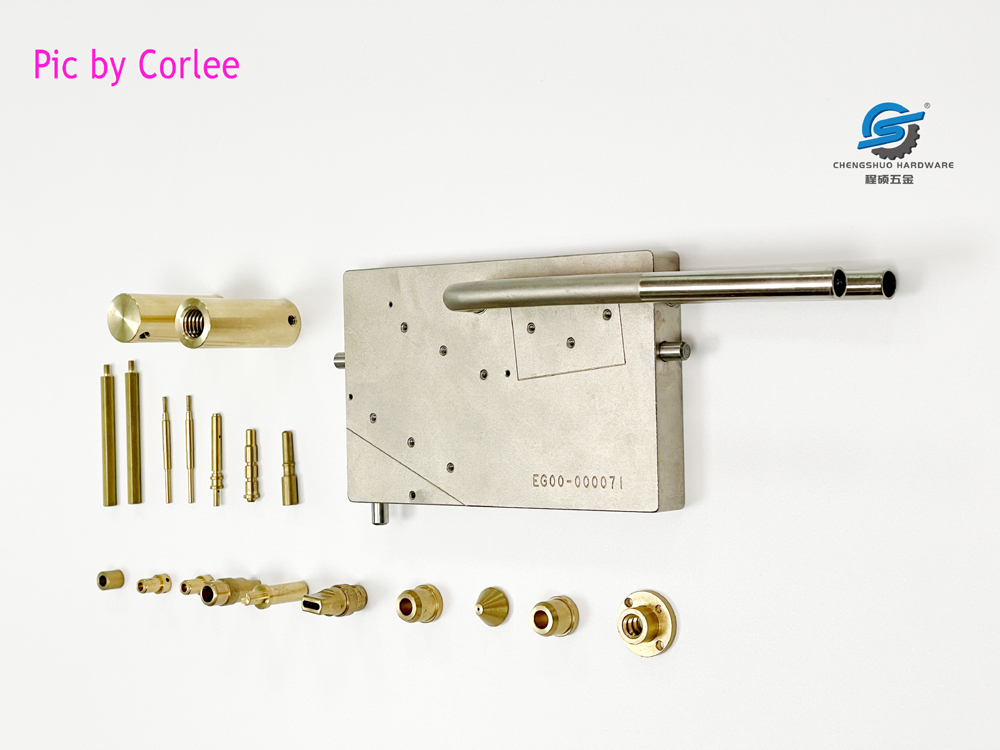

Chengshuo has a milling composite machining center and extensive experiences

in producing high-precision brass products.

If you need to customize brass accessories, please send the design drawings to our factory.We will provide you with professional services.Firstly, our R&D engineers will have a deep understanding of the future usage environment of the brass products needed produce.

Next, a rigorous composition check will be conducted based on different brass materials. Our R&D engineers and senior mechanical engineers will select appropriate brass models and materials according to the product’s usage environment, product structure, and actual processing feasibility, and create programming codes for the machining.

The brass materials commonly used in our CNC machining centers are as follows:

1. Pure copper

Pure copper is usually soft and ductile, and dilution grade pure copper contains small amounts of various alloying elements. Therefore, this helps to change one or more basic characteristics of pure copper into the desired properties. Similarly, adding other alloying elements to pure copper can also increase its toughness.

The composition of commercial pure copper contains approximately 0.7% impurities. According to the different content of added elements and impurities, their UNS numbers are C10100 to C13000.

Pure copper is most suitable for manufacturing electrical equipment, which includes wires and motors. In addition, this type of copper is also suitable for industrial machinery such as heat exchange.

2. Electrolytic copper

Electrolytic copper originates from cathode copper, which refers to copper refined by electrolysis. Generally speaking, this process involves injecting copper compounds into a solution and applying sufficient electrical energy to help purify the copper material. Therefore, the impurity content of most electrolytic copper is lower than that of other grades of copper.

Among all electrolytic copper, C11000 is the most common type, with metal impurities (including sulfur) typically less than 50 parts per million. In addition, they also have high conductivity, up to 100% IACS (International Annealed Copper Standard).

Its excellent ductility makes it suitable for electrical applications, including winding, cables, wires, and busbar.

3. Oxygen free copper

Compared to other types of copper, oxygen free copper contains almost no oxygen. In most cases, anaerobic copper grades include many high conductivity electrical copper components. However, C10100 and C10200 are the most common.

C10100, also known as Oxygen Free Electronic Copper (OFE), is a pure copper with an oxygen content of approximately 0.0005%. In addition, it is also the most expensive among these copper grades. In addition, C10200, also known as oxygen free copper (OF), has an oxygen content of approximately 0.001% and a high conductivity.

These oxygen free copper materials are manufactured using high-quality cathode copper through induction melting. During the production process, cathode copper melts under non oxidizing conditions covered by graphite bath. Oxygen free copper has high conductivity and is most suitable for use in high vacuum electronic devices, including emission tubes and glass metal seals.

4. Easy to cut copper

This copper material is composed of various alloying elements. The main elements include nickel, tin, phosphorus, and zinc. The presence of these elements helps to improve the machining of this copper material.

In addition, free cutting copper materials also include copper alloys such as bronze and brass. Please note the following points:

Bronze is an alloy of copper, tin, and phosphorus, known for its hardness and impact strength;

Brass is an alloy of copper and zinc, which has excellent machining and corrosion resistance;

Easy cutting copper materials are suitable for processing various copper parts, including machined electrical components, gears, bearings, automotive hydraulic components, etc.

5. Customized brass profiles with special ratios

Customized processing of brass materials that meet the requirements of different countries or industries.

For example, the lead-free bismuth brass customized by Chengshuo for customers belongs to lead-free and easy to cut copper. It can be cut without containing lead, thus meeting machining requirements and achieving a bright surface with high precision tolerance. It should be easy to cut and free of burrs.

CNC machining technology for common copper products

1. Copper parts milling processing

CNC milling is an automatic machining process that can control the movement and feed rate of rotating cutting tools. When CNC milling copper, the tool rotates and moves on the surface of the copper material. Then, the excess copper material is slowly removed until it forms the desired shape and size.

CNC milling is the most common method in copper alloy machining, as copper alloys have good machining and can process precision and complex parts. Double edged hard alloy end mills are usually used to mill copper.

Cheng Shuo’s mechanic also uses self-made fixtures to achieve copper products with different design features, and has rich experience in the implementation of various structures such as grooves, holes, and flat contours.

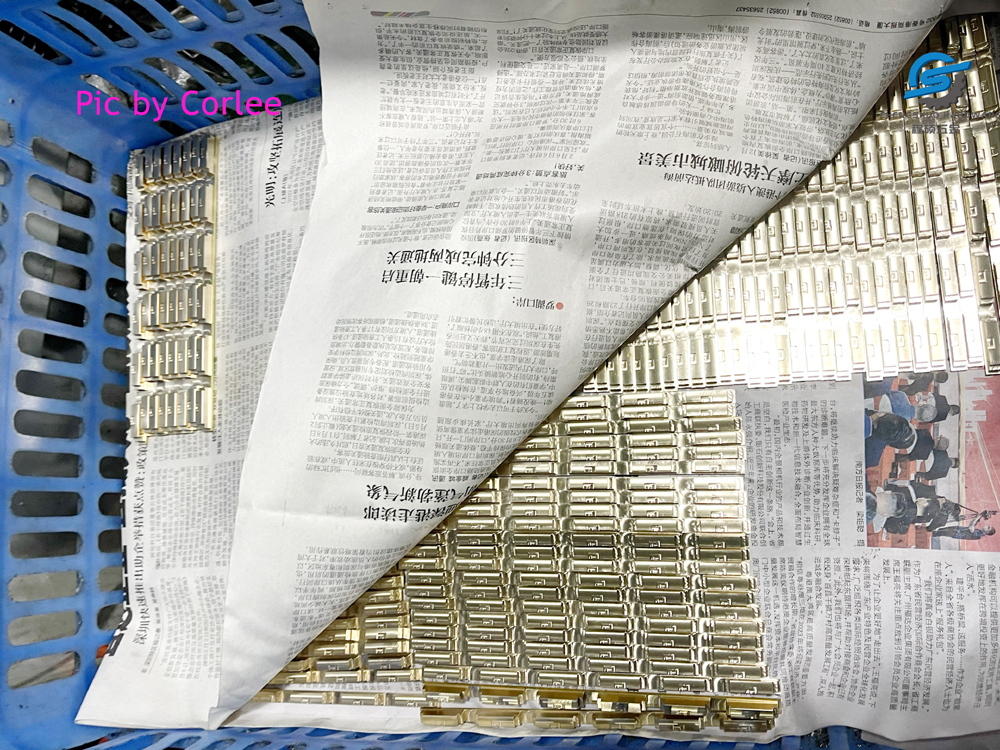

2. Turning processing of copper products

Chengshuo hardware is a senior lathe engineer with rich experience in turning. The copper material is fixed in the cutting tool’s fixed position, and the copper workpiece is turned at a set speed. With the assistance of turning fluid, cylindrical brass parts are completed.

Turning is suitable for various copper alloys and can quickly manufacture high-precision copper parts. In addition, this process also has cost-effectiveness. Therefore, CNC turning copper is suitable for manufacturing many electronic and mechanical components, such as wire connectors, valves, busbars, heat sinks, etc.

Post time: Nov-29-2023