Drawing data required for customized screws from Chengshuo hardware CNC machining center

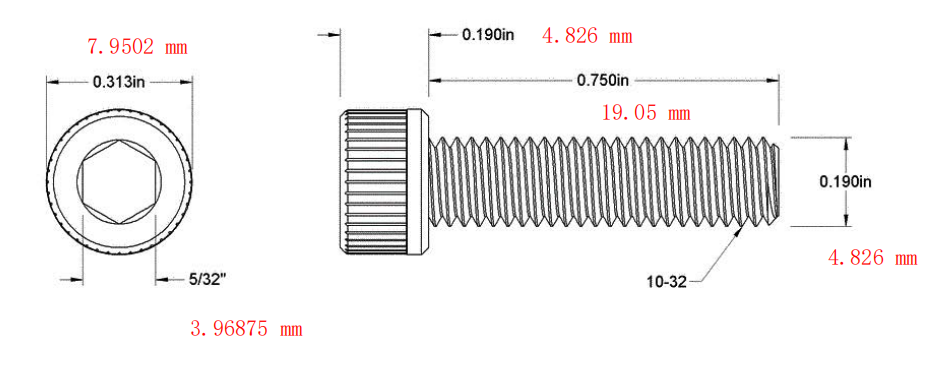

1 .Determine the length and diameter of the screw

When customizing screws, the first step is to determine the length and diameter of the screws. The length of a screw is usually determined by the thickness of the workpiece and the required embedding depth, while the diameter is determined by the size of the hole. Reasonable selection of length and diameter can ensure the connection strength of screws.

2. Choose the appropriate thread type

When selecting thread types, it is necessary to consider the differences in load-bearing capacity of different thread types in different usage environments. For example, for precision instruments and light mechanical equipment, fine threads are usually used; For fields such as automobiles and mechanical equipment, coarse threads are required.

3 Choose appropriate materials

The selection of screw materials depends on their usage environment and load-bearing requirements. Commonly used materials include carbon steel, stainless steel, alloy steel, etc. When selecting materials, factors such as corrosion resistance, strength, and stiffness need to be considered.

4. Determine the shape and type of screw head

Different screw head shapes and types are suitable for different applications. When selecting screw heads, it is necessary to consider the usage environment and application requirements, and choose the appropriate shape and type of screw heads to ensure the quality and reliability of the screws.

5.Consider the usage environment and load-bearing requirements of screws

The usage environment and load-bearing requirements of screws determine their quality and reliability. When customizing screws, it is necessary to consider factors such as temperature, humidity, and oxidation in the usage environment, and determine the quality and type of screws based on load-bearing requirements.

In summary, determining multiple parameters such as length, diameter, thread type, and material of screws is an important step in screw customization. These parameters need to be comprehensively considered in conjunction with the usage environment and load-bearing requirements to ensure the quality and reliability of screws.

Customized Screw Products by Chengshuo Hardware FYR

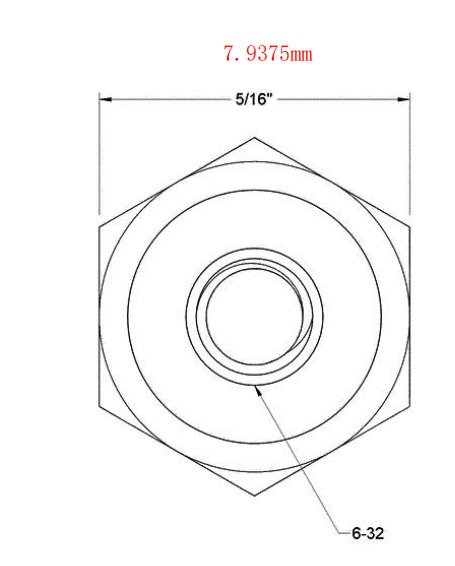

Customization of Hex screws & Nuts

Hexagonal screws are usually used for fixing products in different industries.

According to the customer's usage scenarios, we can provide different treatments for hexagon screws, such as passivation, polishing, electrolysis, galvanizing, heat treatment, hardening, quenching and cooling, chromium plating, titanium plating etc.

Common custom styles for hexagonal screws include: Rocket head screw, Countersunk screw,(round head with concave hexagonal head), straight flat hexagonal head, concave convex character with logo, etc.

In addition, in Chengshuo hardware can customize logos or product codes for your screws, using CNC precision engraving or laser marking to meet your logo requirements.

Post time: Nov-25-2023