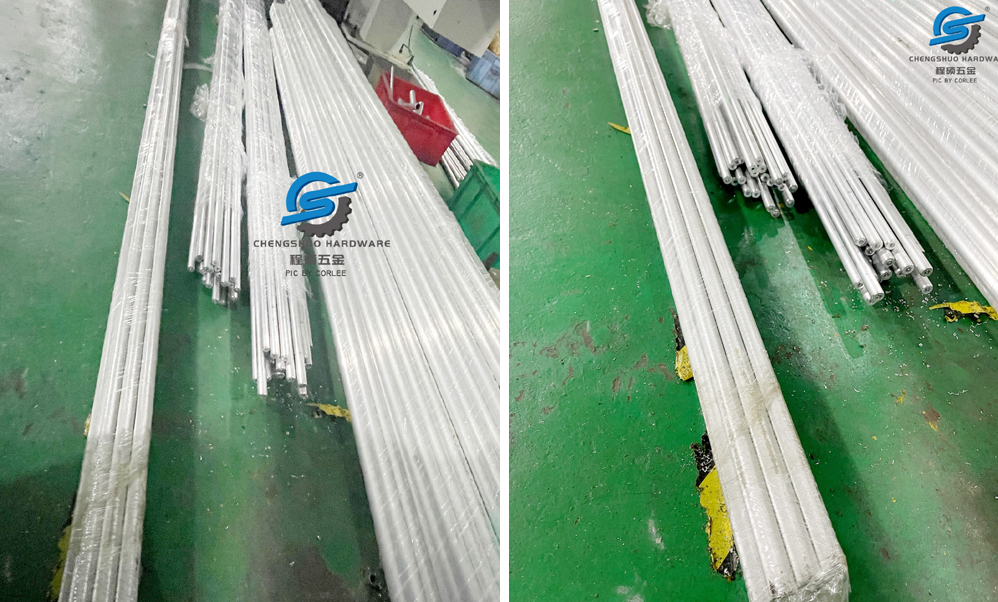

Mechanical engineers need to pay attention to the characteristics of various materials during processing. Cheng Shuo’s senior engineers have rich industrial knowledge about processing raw materials.

This article will introduce to you the characteristics and uses of processed aluminum grades commonly used by Cheng Shuo Hardware engineers.

Characteristics And Uses Of Processed Aluminum Grades

High Purity Aluminum

Commonly used grades include 1A99, 1A97, 1A93, 1A90, 1A85, etc. High-purity aluminum for industrial use, the aluminum content can be as high as 99.99% (mass fraction). Mainly used in scientific research, chemical industry and some other special purposes, such as the production of various electrolytic capacitor boxes, acid-resistant containers, etc. Products include plates, strips, tubes, boxes, etc.

Industrial Pure Aluminum

1060,1050A,1035,1200,8A06,1A30,1100

Pure Aluminum has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, cannot be strengthened by heat treatment, and poor processability; it can be gas welded, hydrogen atom welded and contact welded, not easy to needle weld, and can easily withstand various pressure processing and Deep drawing and bending. It is used to not bear load but requires certain characteristics. Such as structural components with high plasticity, high corrosion resistance or electrical conductivity and thermal conductivity, such as gaskets, capacitors, tube isolation covers, electric wires, wire cores, etc. 1A30 is mainly used for pure aluminum diaphragms in the aerospace industry and weapons industry. 1100 plates and strips are suitable for making various deep drawing products.

Anti-Rust Compound

5A02, 5A03 has higher strength than 3A21, high plasticity and corrosion resistance, cannot be strengthened by heat treatment, and has good weldability (The weldability of 5A03 is better than that of 5A02), the workability is better in the cold work hardened state, the processability is poor in the annealed state, and it can be polished. Medium-strength welding parts, cold stamped parts and containers, skeleton parts, welding rods, rivets, etc. used for working under liquids.

Duralumin

2A16, 2A17

Heat-resistant duralumin has low strength at room temperature but high creep strength at high temperatures. It has high plasticity in the hot state and can be strengthened by heat treatment. 2A16 has good spot welding, seam welding and arc welding performance, low corrosion resistance and good processability. It is used for parts working at 250~350C, such as axial compressor blades and discs; plates are used at room temperature Or welded parts working at high temperatures, such as containers, airtight cabins, etc. 2A17 cannot be used for welding and is used for forgings and stampings requiring high strength.

Forged Aluminum

2A50

High-strength forged aluminum has high plasticity in the hot state, is easy to forge and stamp, and can be strengthened by heat treatment; has good process performance and good corrosion resistance, but has a tendency of intergranular corrosion; processability and spot welding and seam welding The performance of contact welding is good, but the performance of electric welding and gas welding is not good. For forgings and stampings with complex shapes and medium strength.

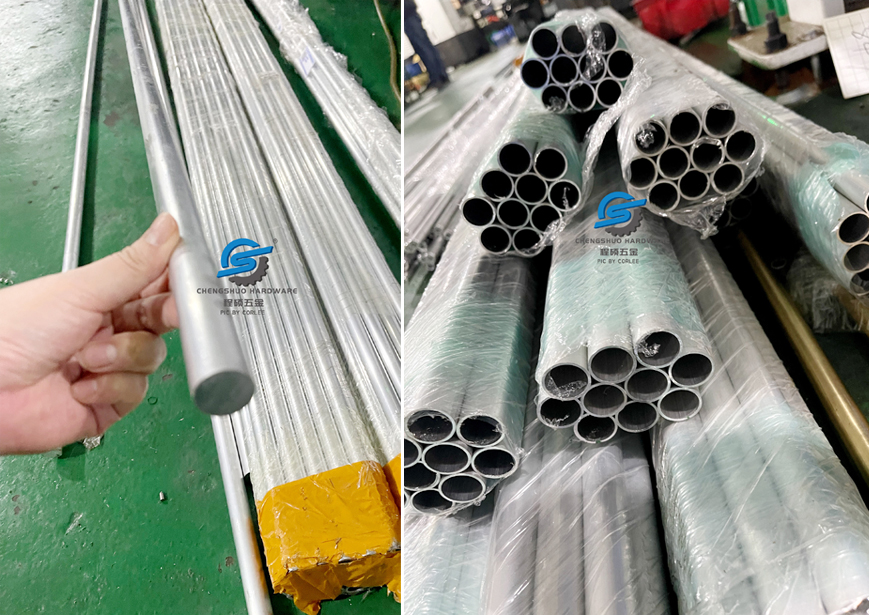

6061, 6063

6061 is used for parts with medium strength (Rm≥270MPa), working in the range of -70~+50℃ and requiring qualified corrosion resistance in humid and seawater media (such as helicopter propeller blades, seaplane wheel boxes)

6063 is used for parts that do not require high strength (Rm≥200MPa), good corrosion resistance, beautiful decorative surface, and work at -70-+50℃. It can be used to decorate aircraft cockpits and is widely used in window frames, door frames, elevators, furniture, etc. in civil buildings. After special mechanical heat treatment, the alloy has higher electrical conductivity and is widely used in the electrical industry.

The common features of 6061 and 6063 are medium strength and excellent weldability. It has good corrosion resistance and cold workability and is a widely used alloy.

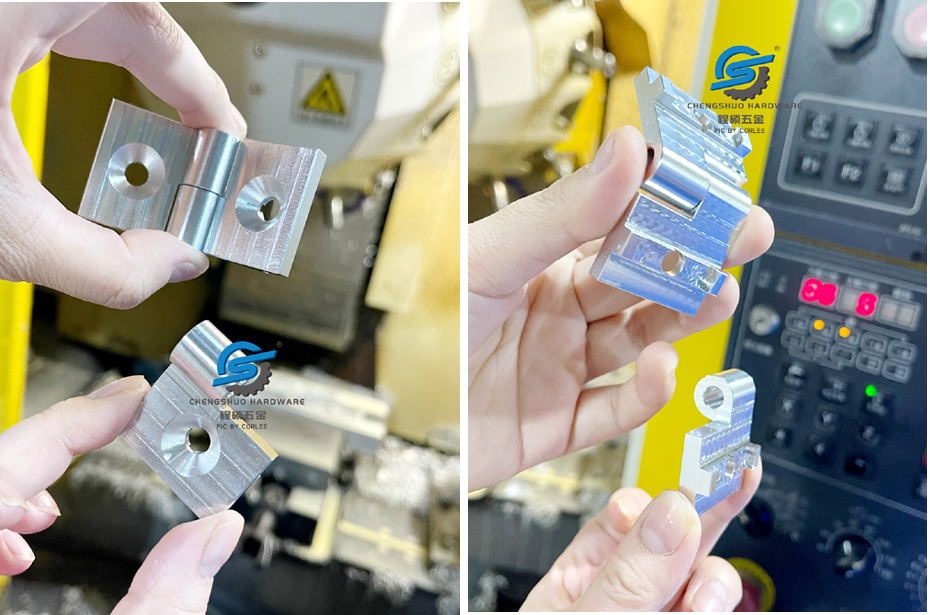

Many projects finished in Chengshuo made from 6061 aluminum. Aluminum Machining Parts are normal products in Chengshuo hardware, after finished machining we can also custom sand blasting & anodizing.

Super Duralumin

7A03 superduraluminum rivet alloy can be strengthened by heat treatment, has high shear strength, acceptable corrosion resistance and processability, and is not limited by heat treatment time during riveting. Rivets for stressed structures. When the working temperature is not higher than 125℃, it can be used as a substitute for 2A10 rivet alloy.

Special Aluminum

4A01 is a low-alloyed binary aluminum-silicon alloy with a silicon content of 5%. Its mechanical properties are not high, but its corrosion resistance is very high; it has good pressure processing properties. Suitable for making welding rods and welding rods, used for welding aluminum alloy products.

Post time: Jun-05-2024