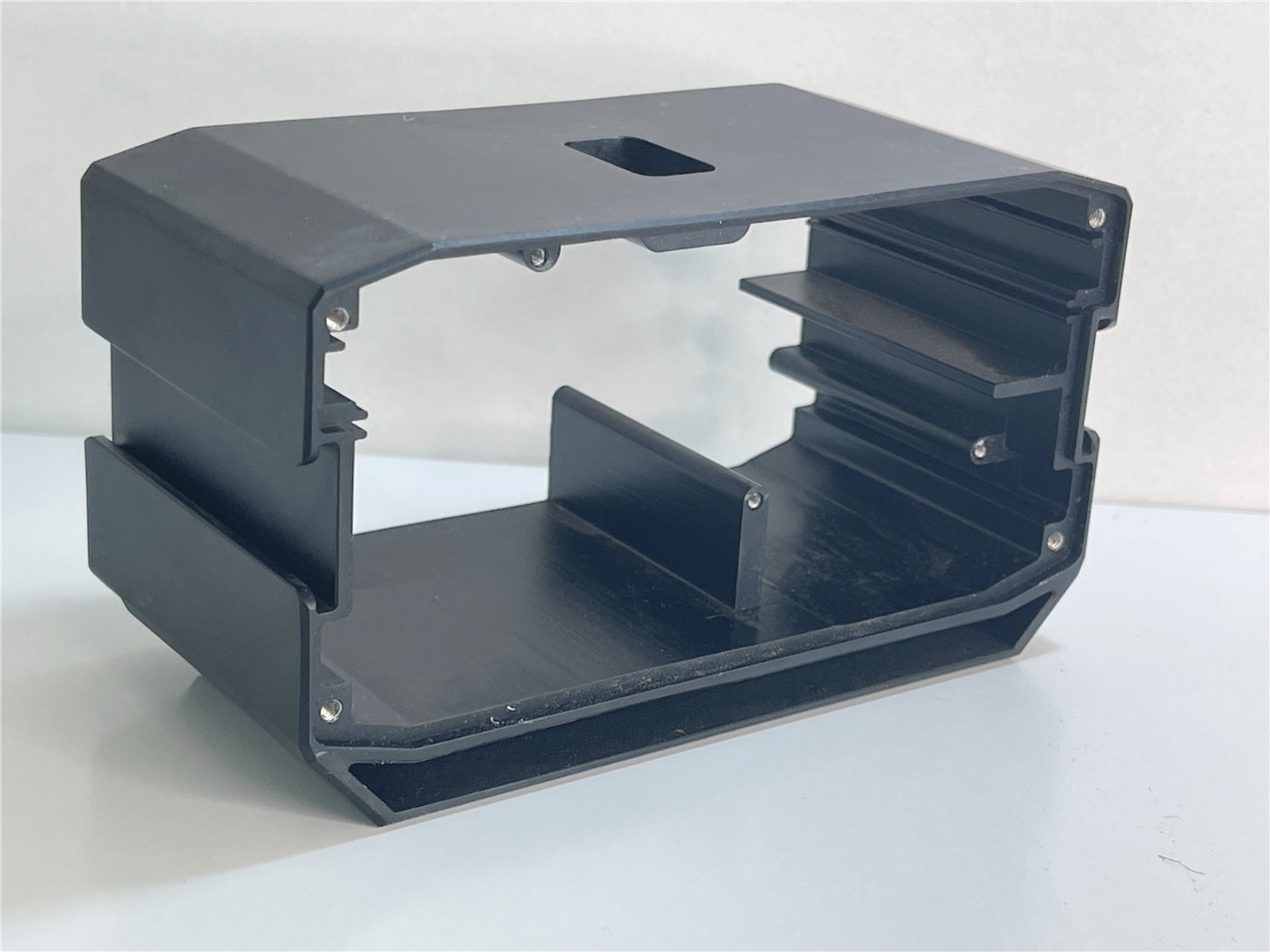

Custom Electroplated Baking Varnish Extrusion Electronic Board Enclosure Parts

Parameters

| Product Name | Custom Electroplated baking varnish Extrusion electronic board enclosure parts | ||||

| CNC Machining or Not: | Cnc Machining | Type: | Broaching, DRILLING, Etching / Chemical Machining. | ||

| Micro Machining or Not: | Micro Machining | Material Capabilities: | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Stainless stell, steel Alloys | ||

| Brand Name: | OEM | Place of Origin: | Guangdong, China | ||

| Material: | Aluminum 6061 | Model Number: | Aluminum cs071 | ||

| Color: | Black | Item Name: | Aluminum cs071 electronic board enclosure parts cnc | ||

| Surface treatment: | Painting | Size: | 3mm - 10mm | ||

| Certification: | IS09001:2015 | Materials Avaliable: | Aluminum Stainless Plastic Metals Copper | ||

| Packing: | Poly Bag + Inner Box + Carton | OEM/ODM: | Accecpted | ||

| Processing Type: | CNC Processing Center | ||||

| Lead time:The amount of time from order placement to dispatch | Quantity(pieces) | 1 - 1 | 2 - 100 | 101 - 1000 | > 1000 |

| Lead time (days) | 5 | 7 | 7 | To be negotiated | |

Advantages

Multiple Processing Methods

● Broaching, Drilling

● Etching/ Chemical Machining

● Turning, WireEDM

● Rapid Prototyping

Accuracy

● Using advanced equipment

● Strict quality control

● Professional technical team

Quality Advantage

● Product Support traceability of raw materials

● Quality control conducted on all production lines

● Inspection of all products

● Strong R&D and professional quality inspection team

Product Details

This electroplated paint extrusion electronic board enclosure part is a CNC metal part with black surface coating, its function is to provide solid protection and beautiful appearance for electronic devices. Here is a detailed description of the product:

1. Using high-quality metal materials

The casing components are made of high-quality metal materials and manufactured through the extrusion process. This gives the casing parts excellent mechanical strength and durability, enabling them to withstand pressure and impact from various environments and protect the internal electronic board from damage.

2. Processed with electroplating and paint baking

The casing components undergo electroplating and baking painting treatment, giving them a black surface coating. This coating not only enhances the product's appearance but also provides corrosion resistance and wear resistance. With this surface coating, the casing parts can effectively resist factors such as moisture, oxidation, and scratches in the external environment, thereby prolonging the overall lifespan of the electronic device.

3. Manufactured using CNC metal processing technology

The casing components are manufactured using CNC metal processing technology. CNC metal processing technology features high precision and automation, ensuring the accuracy and consistency of the casing parts' dimensions. This manufacturing method not only improves production efficiency but also ensures the stability and reliability of the products. When using these casing components, it is necessary to first select the appropriate casing model based on the dimensions and requirements of the electronic device. Then, the casing parts should be properly installed onto the circuit board, ensuring a secure connection with other components. Through proper fixing and installation steps, the casing components can completely enclose and protect the circuit board while maintaining the overall appearance of the device.

To sum up, this electroplating paint extrusion electronic board enclosure part is a CNC metal part with black surface coating, which is manufactured by high-quality metal material, which can provide solid protection and beautiful appearance. With electroplating baking paint treatment and CNC metal processing technology, it has the characteristics of anti-corrosion, wear-resistant and precise. Through correct installation and use, the housing part can effectively protect electronic equipment and improve the quality and appearance of the overall product.