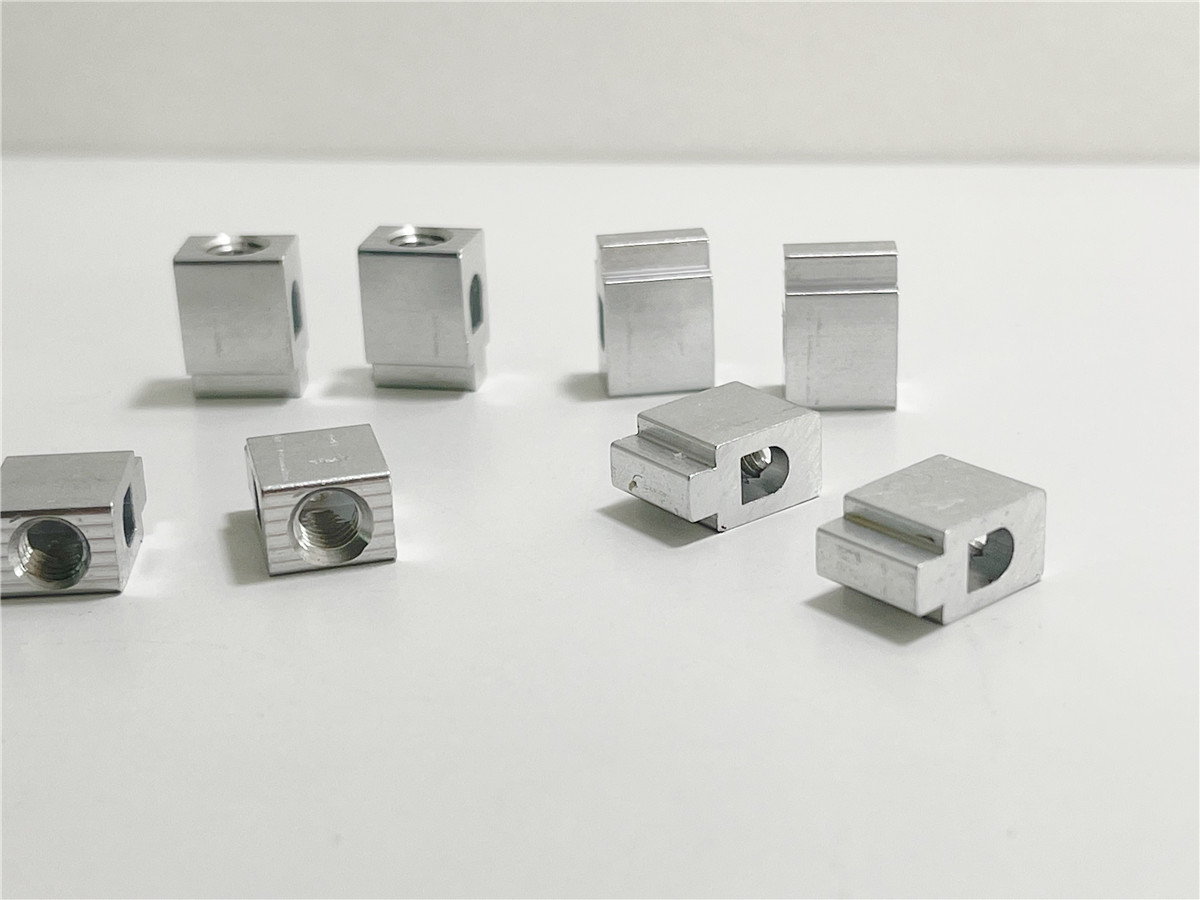

Connecting Seat Fixed Sleeve Ring Fixed Column Screw Clip Aluminum Connector

Parameters

| CNC Machining or Not | Cnc Machining | Tolerance | ±0.005-0.01 | ||

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys | Packing | Rust Preventative PP/PE bags Foams Carton boxes Wooden cases Pallets | ||

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping | Materials Avaliable | Aluminum, copper, iron,steel, titanium alloy, POM, ABS, nylon | ||

| Micro Machining or Not | Micro Machining | Logo | Accept Custom Logo | ||

| Model Number | Aluminum cs113 | Certification | ISO 9001:2015 | ||

| Brand Name | OEM | Application | Automation equipment | ||

| Processing Type | Milling Turning Machining Casting Stamping | Finishing | polishing anodizing | ||

| Sample | within 7days | ||||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10 | 11-100 | 101-1000 | > 1000 |

| Lead time (days) | 5 | 7 | 17 | To be negotiated | |

Product Details

1. High Precision Metal Parts

The aluminum connector is a high-precision metal part, which is usually made of high-quality aluminum material and precision-machined by CNC machining technology. The manufacturing process of this part requires the use of advanced CNC lathe equipment and multi-axis machining technology to ensure its accuracy and shape consistency.

2. Main function: connect different components or components

The main function of this part is to connect different members or components and hold them together. It usually consists of a connecting seat, a fixed collar, a fixed column and a screw clamp. A socket provides a platform to which other components can be attached. The function of the fixed collar and the fixed post is to ensure the stability and reliability of the connection while maintaining a certain degree of friction and tightness. Screw clamps are used to fasten the entire connector to ensure a tight connection.

3. Advantages of CNC machining process

The aluminum connector with fixed sleeve, ring, fixed column screw and clamp aluminum connector made by CNC processing technology has many advantages. First of all, the CNC machining process has high precision and stability, which can ensure the accuracy and consistency of the part size. In this way, the connector can better adapt to different connection requirements and ensure the tightness and stability of the connection.

4. Provides personalized selection and optimization solutions

The turning and custom processing process of the connecting seat, fixing sleeve, fixed column screw clamp aluminum connector provides customers with personalized choices and optimization solutions. Customers can customize connectors of various sizes, shapes and functions according to their own needs and requirements. At the same time, our professional team will provide technical support and advice to ensure the best results in the design and processing of the connector.