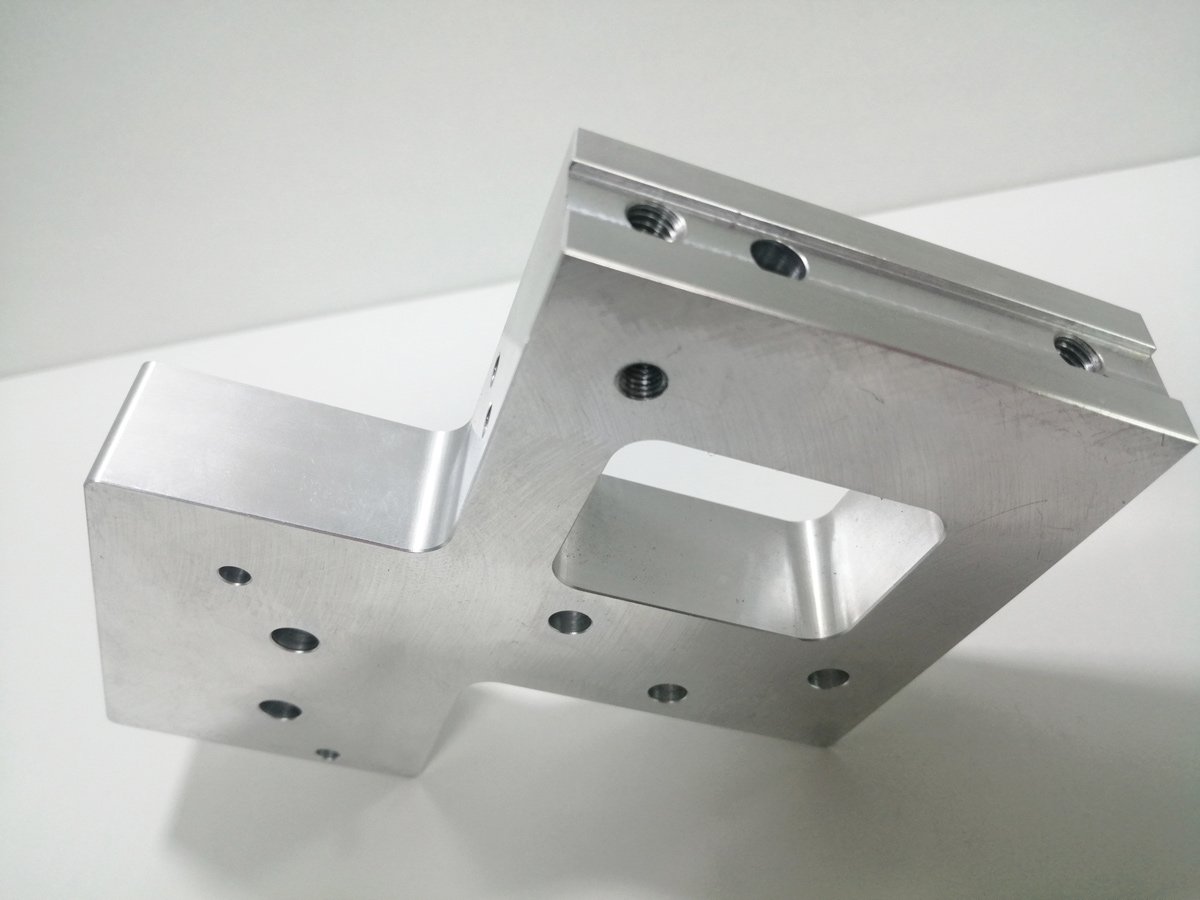

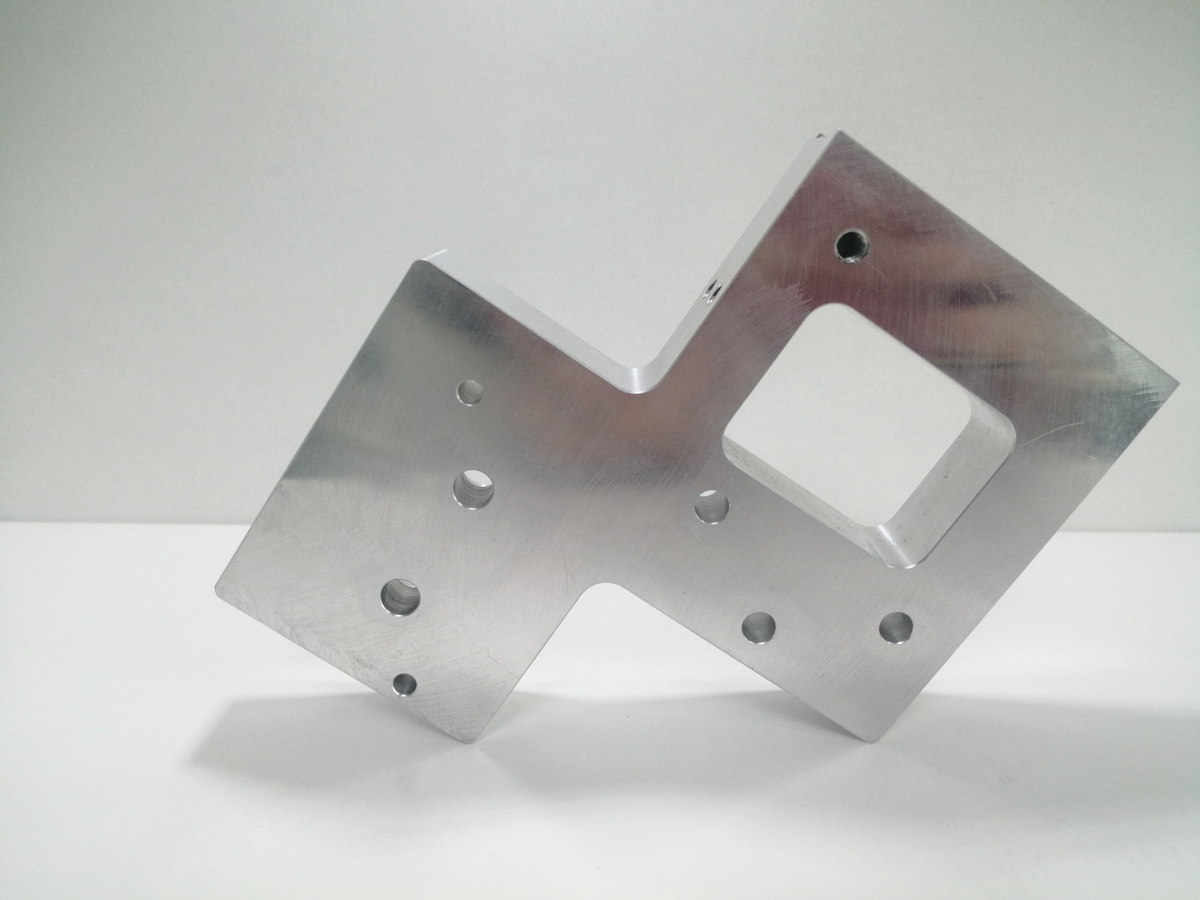

CNC Machining Components Aluminum Parts

Parameters

| CNC Machining or Not | Cnc Machining | Size | 3mm~10mm | ||

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys | Color | SLIVER | ||

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping | Materials Avaliable | Aluminum Stainless Plastic Metals Copper | ||

| Micro Machining or Not | Micro Machining | Surface treatment | Painting | ||

| Model Number | Aluminum cs125 | OEM/ODM | Accecpted | ||

| Brand Name | OEM | Certification | ISO9001:2015 | ||

| Processing Type | Stamping Milling Turning Machining Casting | Processing Type | CNC Processing Center | ||

| Packing | Poly Bag + Inner Box + Carton | Material | Titanium aluminium | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-500 | 501-1000 | 1001-10000 | > 1000 |

| Lead time (days) | 5 | 7 | 17 | To be negotiated | |

More Details

One of the notable advantages of CNC machining components aluminum parts is their versatility. They can be used in a wide range of industries, including aerospace, automotive, electronics, and more. These parts are often employed in the production of various products such as aircraft components, automotive parts, electronic enclosures, and machinery components.The precise and accurate manufacturing tolerances achieved through CNC machining ensure high-quality and consistent parts. The CNC machines can create intricate designs and complex geometries with tight tolerances, resulting in components that fit together seamlessly and function effectively. Aluminum, being a lightweight material, makes these parts ideal for applications where weight reduction is essential. Despite its lightweight nature, aluminum possesses excellent strength and stiffness, making it highly suitable for applications requiring structural integrity. In addition to its mechanical properties, aluminum is also highly resistant to corrosion, increasing the longevity of CNC machining components aluminum parts. This resistance to corrosion makes these parts suitable for use in various environments, including those exposed to moisture, chemicals, and extreme temperatures. Another notable feature of CNC machining components aluminum parts is their aesthetic appeal. The CNC machining process ensures smooth and precise finishes, giving the parts a sleek and professional appearance. This makes them suitable for applications where aesthetic considerations are important, such as consumer electronics or high-end products.

In conclusion, CNC machining components aluminum parts are crucial elements manufactured using CNC machining techniques with aluminum as the primary material. They offer exceptional strength, lightweight properties, durability, and excellent corrosion resistance. These parts have various applications across industries, offering versatility and high-quality manufacturing. Whether utilized for aerospace, automotive, or electronic purposes, CNC machining components aluminum parts provide reliable performance and excellent aesthetics.