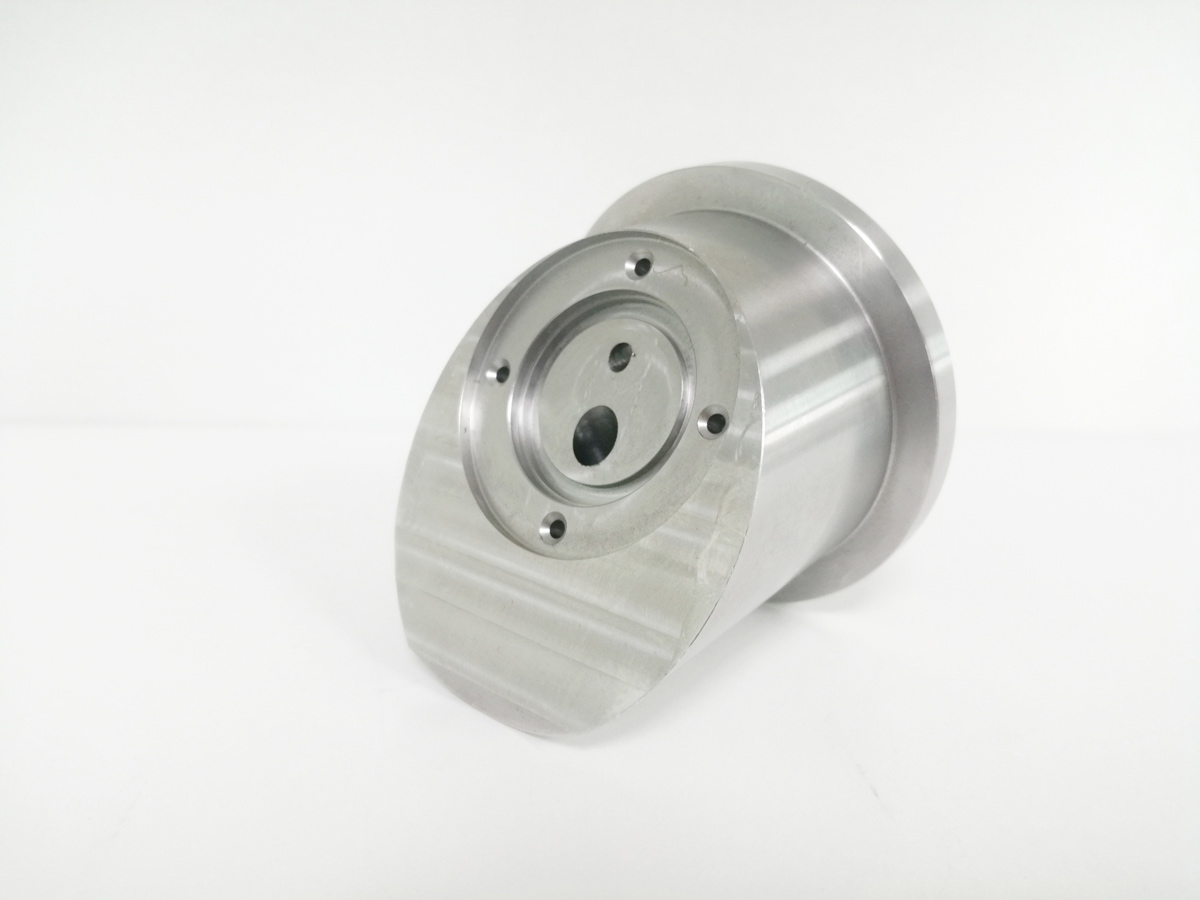

CNC Machining Aluminum Connector Anodizing Processing Customization

Parameters

| CNC Machining or Not | Cnc Machining | Size | 3mm~10mm | ||

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys | Color | Yellow | ||

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping | Materials Avaliable | Aluminum Stainless Plastic Metals Copper | ||

| Micro Machining or Not | Micro Machining | Surface treatment | Painting | ||

| Model Number | CSL009 | OEM/ODM | Accecpted | ||

| Brand Name | OEM/ODM | Certification | ISO9001:2015 | ||

| Item Name | CSL009 | Processing Type | CNC Processing Center | ||

| Material | aluminum | Packing | Poly Bag + Inner Box + Carton | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-500 | 501-1000 | 1001-10000 | > 10000 |

| Lead time (days) | 5 | 7 | 7 | To be negotiated | |

Characteristics

High quality: We adopt advanced CNC machining technology and equipment to ensure the accuracy, stability, and durability of our products. This allows our products to perform exceptionally well in various application scenarios and provide reliable solutions for our customers.

Customization: We can design and customize our products according to specific needs and requirements of our customers. You can choose the shape, size, hole positions, and other specifications of the connectors based on your design requirements. Our technical team will work closely with you to ensure that the final product meets your expectations.

Corrosion resistance: We offer various color options of anodized coatings to meet your branding or market needs. Our anodizing process also enhances surface hardness and wear resistance, thus extending the lifespan of the connectors.

Exquisite appearance: The anodizing process gives our products a wide range of color choices, making them visually appealing. This can enhance brand image and increase market attractiveness for certain customers.

Systematic service: We provide comprehensive customer support services, including technical consultation, pre-sales, in-sales, and after-sales support. Our team collaborates closely with customers to ensure that our products meet their needs and provide timely solutions and support.

Advantages

Improved production efficiency: High-quality products and customized features help customers optimize their production processes and improve efficiency.

Cost reduction: Products with strong corrosion resistance and stability can reduce maintenance and replacement costs, lowering customers' operating costs.

Enhanced market competitiveness: The high quality, customization, and visually appealing appearance of our products can help customers stand out in the market and gain a competitive edge.

Improved customer satisfaction: Our customer support services help customers solve problems, meet their needs, and provide professional technical consultation and advice, thereby enhancing customer satisfaction.