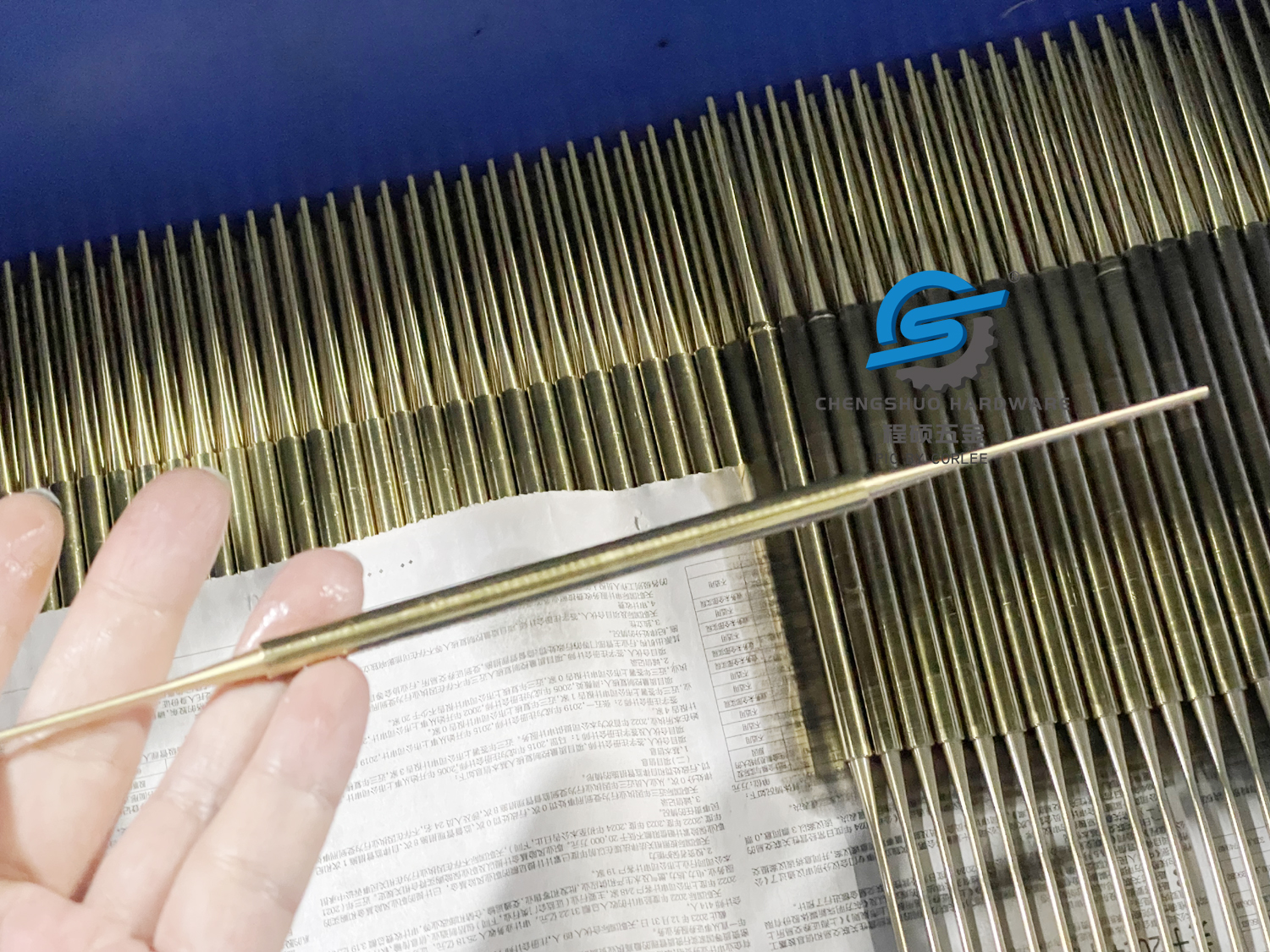

Brass Thimble Fixed Pin machined by Chengshuo 5 five axis automatic lathes-By Corlee

Custom Brass Thimble Fixed Pin Machining Factory CNC Milling Turning Chengshuo Hardware Machined

Overview of the machining process using a five-axis automatic lathe:

1. Setup: Prepare the five-axis automatic lathe for machining operations, ensuring that the workpiece fixture and cutting tools are properly installed and aligned.

2. Loading: Load the brass material into the lathe, ensuring a firm clamping to minimize vibration and ensure precision during machining.

3. Tool path programming: Develop a tool path program to use the five-axis function to efficiently machine the complex features of the brass ejector pin fixing pin.

4. Turning and Milling: Utilize a five-axis lathe to perform turning and milling operations in a single unit, allowing complex geometries, undercuts, and other complex features to be machined.

5. Tool changing: Use the automatic tool changing device of the lathe to switch between different tools according to the needs of various processing processes such as turning, drilling, and milling.

6. Quality control: Quality control measures are implemented during the process to ensure that the machined brass thimble retaining pins meet the specified dimensional tolerances and surface finish requirements.

7. Surface Finishing: If necessary, perform any necessary surface finishing operations such as polishing or deburring to obtain the desired surface quality.

Using a five-axis automatic lathe to machine brass ejector pins has the advantage of enhanced flexibility and the ability to machine complex geometries in a single unit, ultimately helping to increase efficiency and accuracy.

If you have specific design requirements or tolerances for your brass ejector pins, it is important to ensure that the programming and setup of your five-axis automatic lathe is customized to meet those specifications.

It is important to note that the specific machining operations and parameters for brass ejector pins may vary based on specific design, tolerance and surface finish requirements. Additionally, using the appropriate cutting tools, machining speeds, and brass machining feeds is critical to obtaining high-quality results.