-

cnc machining service

The industry-leading CNC lathe ensures that your products are delivered on time, every time. -

INJECTION MOLDING SERVICE

Rapidly customizing high-quality, cost-effective molded parts. Once mass production is achieved, thetooling will be free. -

SHEET METAL FABRICATION

From durable brackets to intricate panels, Chengshuo delivers the perfect solution for all your sheet metal fabrication needs.

leading the best precision machining factory in dongguan china.

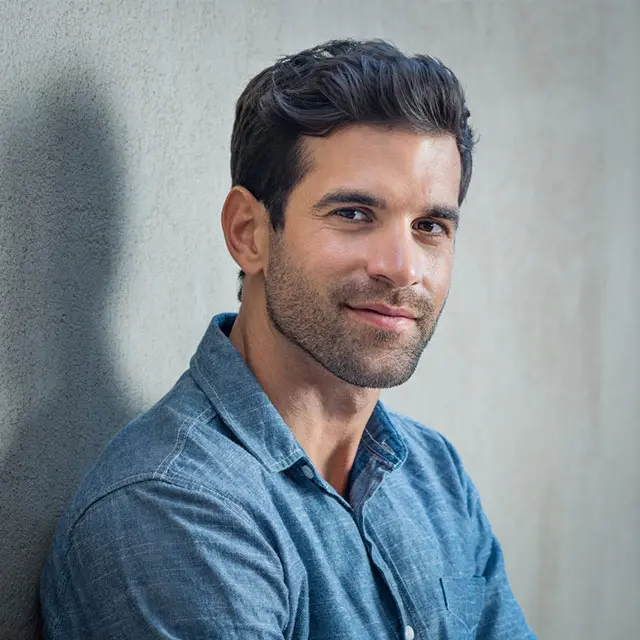

From being a frontline worker to a production supervisor and eventually a company owner, LEI has become an expert in the precision machining industry. He knows how to lead his team to quickly and accurately understand customer needs, transforming them into perfect products.

-

Solving Any Engineering Challenge

Lei can determine the optimal production and manufacturing methods for products at a glance.

-

Solving Any Engineering Challenge

Lei can determine the optimal production and manufacturing methods for products at a glance.

- Putting Customer Benefit First

- Always Pursue Employee Satisfaction at Our Company

our team members

-

The leader of Chengshuo, with 20 years of experience in hardware industry, Mr Lei has a comprehensive understanding of the implementation of hardware products, a unique thoughts of the development and implementation of the manufacturing industry, and the specific production process of the product. Not only rich experience & strong design capabilities for product implementation but also he proficients in project research, cost solutions, and a master of mold design.

Mr. LeiGM & Chief Engineer

Senior Engineer -

CFO of Chengshuo, cost analysis & management of hardware industry for 15 years. Experienced in procurement, with strict & professional control over raw material & product processing treatments, as well as overall project costs, brings more refined management to clients and achieve goals of project cost control.

Yanna TangCFO

-

20 years experience in the research & production of lathe products. Mr Li is familiar with various materials, quick quotations based on drawings & samples, offering the advantageous prices, good at optimizing product structure, customize & implement processes, reduce costs, improve drawings for projects. He also manages Chengshuo’s lathe department, supervises the schedules, programming, and each lathe department projects, to ensure that projects are going on schedule & with high quality.

Mr. LiSenior Engineer

Supervisor of Lathe & Automatic Lathe Department -

15 years of experience in CNC milling production. Mr Liang provides the quick quotations based on drawings & samples, and offers the reasonable & advantageous quotations. He is also good at processing & sorting products of different materials, skills in designing product implementation. Meanwhile, he develops reasonable schedule planning & guidance for two shifts of mechanical engineers, and comprehensively manage the daily operations of Chengshuo CNC machining center. Rich industry experience in producing with different materials & processing methods.

Mr. LiangSenior Engineer

Supervisor of CNC Milling Center Department

-

Competitive Pricing

We offer competitive pricing without compromising on quality. Our efficient manufacturing processes enable us to provide cost-effective solutions for your custom CNC, injection molding, and sheet metal parts.

-

Reliable Lead Times

We understand the importance of timely delivery. With our commitment to adhering to deadlines and efficient production management, we guarantee reliable lead times for your customized parts, ensuring smooth project timelines.

-

Quality Assurance

Quality is at the core of everything we do. Our stringent quality control measures and skilled workforce ensure the production of reliable and high-quality CNC, injection molding, and sheet metal components, meeting your exact specifications.

WE MADE PARTS CUSTOMIZATION EASIER FOR YOUR BUSINESS

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur